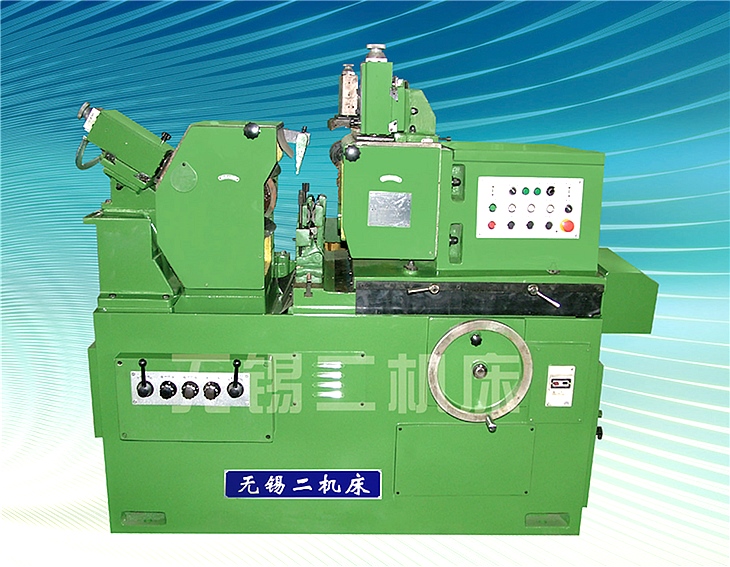

主要特点

ain Characteristics

1.该机床用于各种圆柱体零件的通磨座削及圆锥体.成形回转体零件的切入磨削。适用于成批和大量生产需要。

2.砂轮主轴轴瓦为五片式动压滑动轴瓦。承载力大、刚度高。

3.导轮主轴轴承为1:30经体式滑动轴承。承载能力大.精度高。

4.导轮架在水平方向可作小角度回转,在磨削小锥度的工件时砂轮可以不必修整成锥形,提高砂轮利用率和减少修整时间。

5.导轮变速采用交流变频调速,可实现无级调整。

6.砂.导轮修整器往复均采用液压传动,无级调整。

7.备有自动切入磨削装置,可作半自动循环工作。

This machine tool applies to continuous grinding of various cylinders and cut grinding of cone and forming rotary

parts, for the needs of bulk and mass production

The main shaft bearing of the grinding wheel is 5 dynamic sliding type, with large bearing capacity and high hardness.

The main shaft bearing of guide wheel is 1:30 integral sliding type, with large bearing capacity and high precision.

The wheel frame can rotate horizontally, so wnen grinding small parts, there is no need to adjust the grinding

wheel into cone, so as to increase its utilization ratio and decrease trimming time.

The guide wheel gearshift is AC controlled, thus realizing non step adjustment.

Grinding and guide wheel trimmer reciprocating adopts hydraulic transmission and non step adjustment.

Equipped with automatic cut and grinding equipment, it can work semi-automatically periodically.