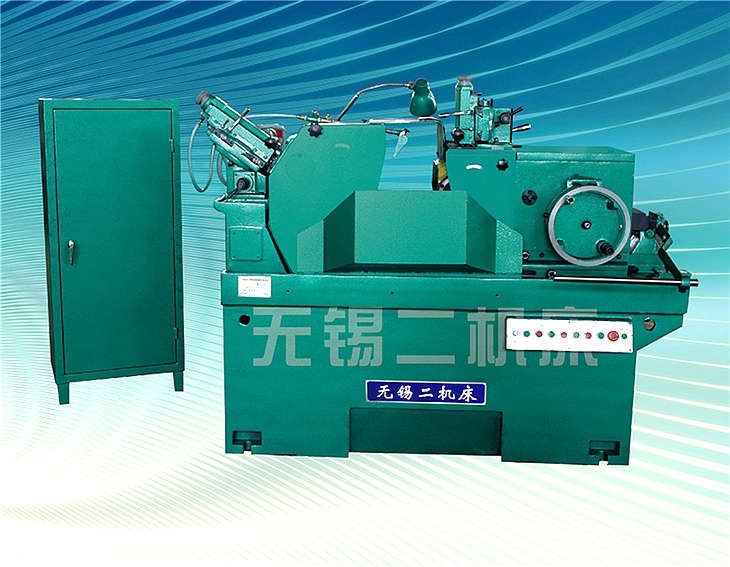

主要特点

ain Characteristics

1.机床采用砂轮架固定,导轮架移动进给布局:

2.砂轮为悬臂式结构.砂轮主轴采用多片式长轴瓦动压油膜轴瓦:

3.导轮主轴前轴承采用锥面滑动径向轴承,后轴永为径向止推组合球轴瓦:

4.横进给机构采用含氟贴塑导轨.迸给用差动丝杆

5.砂轮和导轮修整均为液压传动,并附有仿型装置,适合切入磨削多合阶工件

6.导轮主轴变速买用交换齿轮(可根据用户需要设计交频调速):

7.机床符合国家电气安全标准,采用独立电柜。

The layout of the machine is grinding wheel fixing and wheel frame moving feeding.

The grinding wheel is of cantilever structure; wheel main shaft adopts muitiple major axis hydrodynamic oil-film

bearing.

Front bearing of wheel spindle is cone sliding radial bearing while back bearing is radial thrust combination ball

bearings

Transverse feeding mechanism is Guide Rail Pasted with Fluorin Plastic, feeding differential screw

Maintenance of grinding wheel and guiding wheel is hydraulic transmission with copy device, applicable to plunge

grinding multi-level work piece.

The main shaft speed gear is changeful-gear (it can be frequency controlled according to customers' require-

ments).

This machine conforms to the State safety standard and its electric cabinet is independent.